The Guideline of Application of Thai Weaving Wisdom with Uses of Rubberwood in the Design of Contemporary Thai Architecture

Main Article Content

Abstract

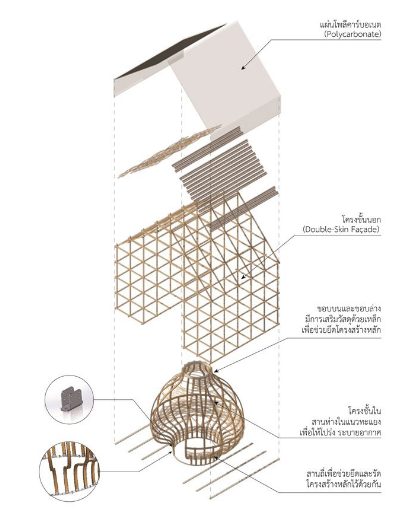

This research aims to study Thai weaving patterns for the application of rubberwood as an architectural element and structure that suitable for the modern style and outline of Thai architecture. By studying the feasibility of using rubberwood, including qualitative data and the nature of wood processing which is the result of current technology, it was found that problems with moisture, strength, and suitable size and shape must be taken into account to prevent damage from insects, weevils, and fungi which can cause warping and get short straight pieces of wood. In order to be used as an architectural element or structure, it must be developed to acquire the size and shape suitable for use in the form of a Structural Composite Lumber (SCL). By stacking several layers of wood and using glue as a binder to obtain suitable form and size for architecture, it was found that Glued Laminate Timber (Glulam) method can lead to curved shapes such as the Grid-Shell Structure, which is consistent with the pattern of Thai basketry. The curved surface area works as the main structure. The weight is distributed over various parts with a band to help for holding the structure together. After the construction of a model of a rubberwood pavilion, problems and limitations were found in the design, consisting of 1. The radius of the wood curvature; 2. Size and length; 3. Deformation after removing from the template. The results of the evaluation after 1 year showed that the overall structure was still strong and accessible but there was a mold problem in the wood, especially in the area that was exposed to rain and wet.

Downloads

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

All material is licensed under the terms of the Creative Commons Attribution 4.0 International (CC-BY-NC-ND 4.0) License, unless otherwise stated. As such, authors are free to share, copy, and redistribute the material in any medium or format. The authors must give appropriate credit, provide a link to the license, and indicate if changes were made. The authors may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use. The authors may not use the material for commercial purposes. If the authors remix, transform, or build upon the material, they may not distribute the modified material, unless permission is obtained from JARS. Final, accepted versions of the paper may be posted on third party repositories, provided appropriate acknowledgement to the original source is clearly noted.

References

Alister, D., & Barbara, L. (2017). Wooden ‘Plyscrapers’ Challenge Concrete and Steel. Reuters. Retrieved from https://www.reuters.com/

Department of Industrial Promotion. (n.d). Weaving Pattern. Bangkok: Department of Industrial Promotion.

Forest Industry Organization. (2017). Wood quantity data. Retrieved from http://forestinfo.forest.go.th/

Horayangkura, V. (2012). The Creation of Cultural Heritage Towards the Development of a Modern Thai Architectural Identity. Journal of Architectural/Planning Research and Studies (JARS), 8(1), 1-19.

Kaewkong, B., & Doungpe, M. (1999). Handbook for Mechanical Testing of Wood. Bangkok: Kasetsart University.

Kuijvenhoven, M. T. (2009). A design method for timber grid shells. (MSc Thesis). Civil Engineering, Delft University of Technology.

Leesuwan, V. (1981). Research Report of Wickerwork in Thailand. Bangkok: National Research Council of Thailand.

Oregon Best. (2017). Advanced Wood Product Manufacturing Study for Cross-Laminated Timber Acceleration in Oregon & SW Washington. Retrieved from http://oregonbest.org/fileadmin/media/Mass_Timber/Accelerating_CLT_Manufacturing_in_Oregon___SW_Washington__2017__Oregon_BEST_.pdf

Puvanant, C. (1999). Pre-feasibility study of introducing the Canadian 2 x 4 constructions into Thailand. Bangkok: E.T Publishing.

Soodsa-nguan, M. (1997). Basic Woodworking Techniques. Bangkok: King Mongkut’s Institute of Technology Ladkrabang.

Srisoawanut, A. (2012). Loa-Song, Wickerwork appliances and Change. Bangkok: u-sa-kha-ne.

Vlosky, P. R., Smith, M. P., Blankenhorn, R. P., & Haas, P. M. (1994). Laminated Veneer Lumber: A United State Market Overview. Wood and Fiber Science, 26(4), 456-466.