The Experiment of Heat Transfer in Material Block Made from Agricultural Waste Integrated by Cement

Main Article Content

Abstract

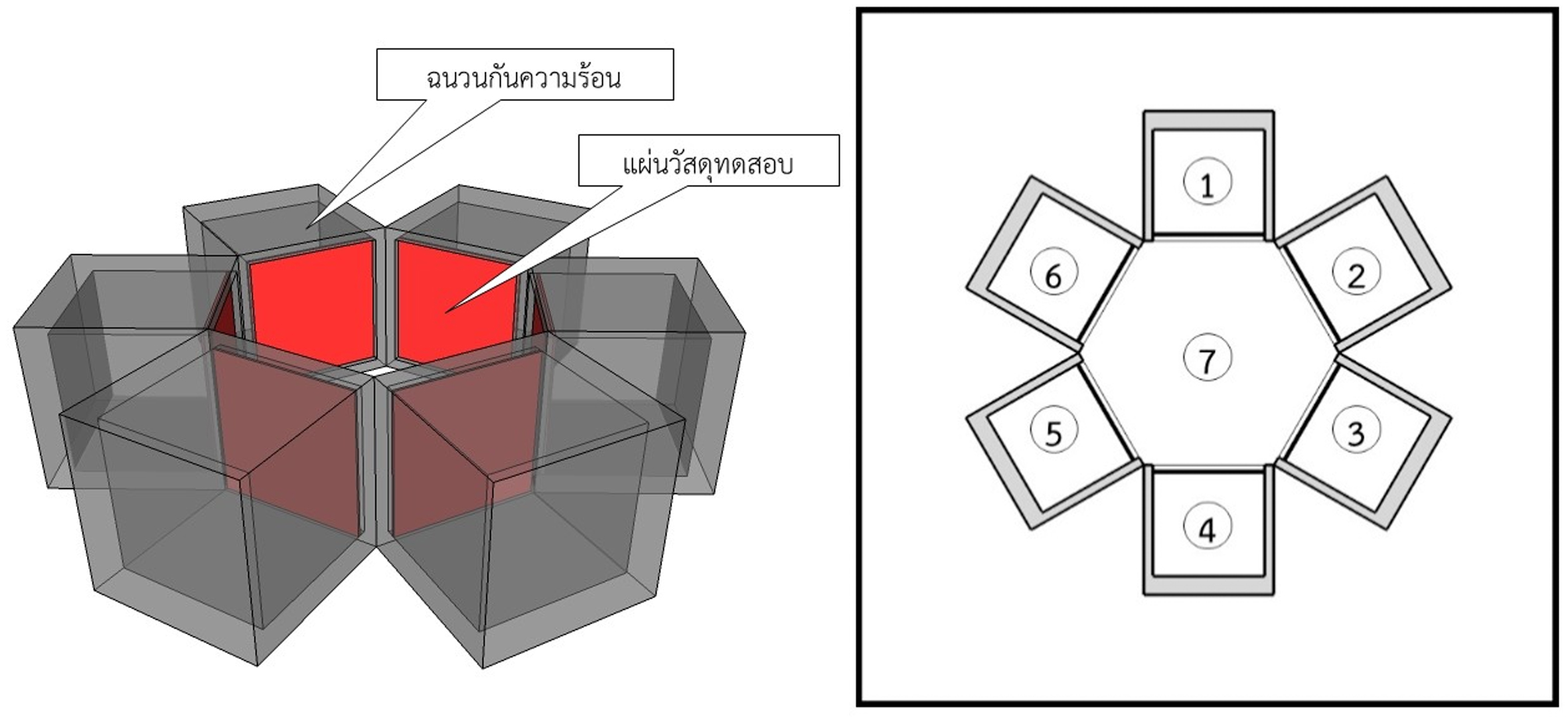

The objective of this research is to observe the quality of heat transfer from various agricultural waste integrated with cement as bonding material. The weight ratio of the mixture between cement and agricultural waste used is 1:0.15. This weight ratio can create the best quality of examined block in the dimension of 60 cm. x 60 cm. with the thickness of 2 cm. This experiment is tested under non-air conditioned condition. Then the thermal conductivity (K-Value) under the controlled indoor-temperature is investigated. The results show that all examined materials have heat-capacity quality with short time lag, because of the thinness of the examined blocks. Also materials that have longer periods of time lag are considered a good thermal insulator. The results of this study show the best to worst examined materials ranking in quality of reducing heat in the non-air conditioner condition as 1) integration of concrete and pulp from vetiver grass 2) integration of concrete and bamboo waste 3) integration of concrete and paper pulp 4) integration of concrete and rice husk ash 5) integration of concrete and rice husk 6) integration of concrete and coffee endocarp. The results of this research should be tested and developed in order to further apply to create building materials that are used with and without air-conditioner condition

Downloads

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

All material is licensed under the terms of the Creative Commons Attribution 4.0 International (CC-BY-NC-ND 4.0) License, unless otherwise stated. As such, authors are free to share, copy, and redistribute the material in any medium or format. The authors must give appropriate credit, provide a link to the license, and indicate if changes were made. The authors may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use. The authors may not use the material for commercial purposes. If the authors remix, transform, or build upon the material, they may not distribute the modified material, unless permission is obtained from JARS. Final, accepted versions of the paper may be posted on third party repositories, provided appropriate acknowledgement to the original source is clearly noted.

References

Boonyathikarn, S. (1999). Techniques of energy saving house design for better quality of life. Bangkok, Thailand: Chulalongkorn University.

Chiang Mai Government Center. (2017). General information of Chiang Mai. Retrieved January, 2017, from https://www.chiangmai.go.th/managing/public/D8/8D01Feb2017150134.pdf.

Kreider, J. F., Curtiss, P. S., & Rabl, A. (2002). Heating and cooling of building design for efficiency. USA: Traylor & Frank Group.

Lertwattanaruk, P., & Tungsirisakul, J. (2007). Effect of natural materials on properties of adobe brick for earth construction. Journal of architectural/planning research and studies (JARS), 5(1), 187-199.

Okino, E. Y. A., Santana, M. A. E., & de Souza, M. R. (2000). Utilization of wastepaper to manufacture low density boards. Bioresource Technology, 73, 77-79.

Ricciardi, P., Torchia, F., Belloni, E., Lascaro, E., & Buratti, C. (2017). Environmental characterisation of coffee chaff, a new recycled material for building applications. Construction and Building Materials, 147, 185-193.

Sangrutsamee, V. (2012). Development of lightweight interlocking blocks from paper pulp waste. Built environment research associates conference, 3, 12-20.

Santamouris, M., & Asimakopoulos, D. (1996). Passive cooling of building. London: James & James.

Srivanit, M., & Auttarat, J. (2016). Classifying spatial homogeneity of thermally-stabilized surface to define differentiation local atmospheric zones in Chiang Mai city. Journal of Architectural/Planning Research and Studies (JARS), 13(1), 1-22.

Stein, B., & Reynolds, J. S. (1992). Mechanical and electrical equipment for buildings. New York: John Wiley & Sons.

Sukjinda, P., Numkrun, K., & Chaivichit, N. (2016). Suitable amount of black rice husk ash for structural concrete work. Building innovation, 1, 8.

Taemthong, W. (2013). Rice straw insulation sheet. KKU research journal, 18(3), 380-390.

Thai meteorological department. (2017). Chiang Mai weather information. Retrieved January, 2017, from https://www.tmd.go.th/index.php.

Yimprayoon, C. (2016). Zero energy building. Journal of Architectural/Planning Research and Studies (JARS), 13(2), 1-30.

Yodnumkhum, W. (2005). Production development of cement composite plates reinforced with wastepaper fibers. Master of science thesis (Civil Engineering), Faculty of industrial education and technology, King Mongkut’s University of Technology Thonburi, Thailand.